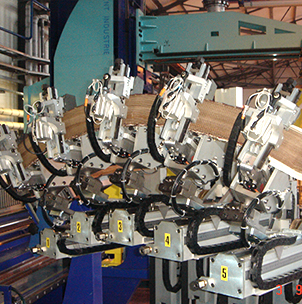

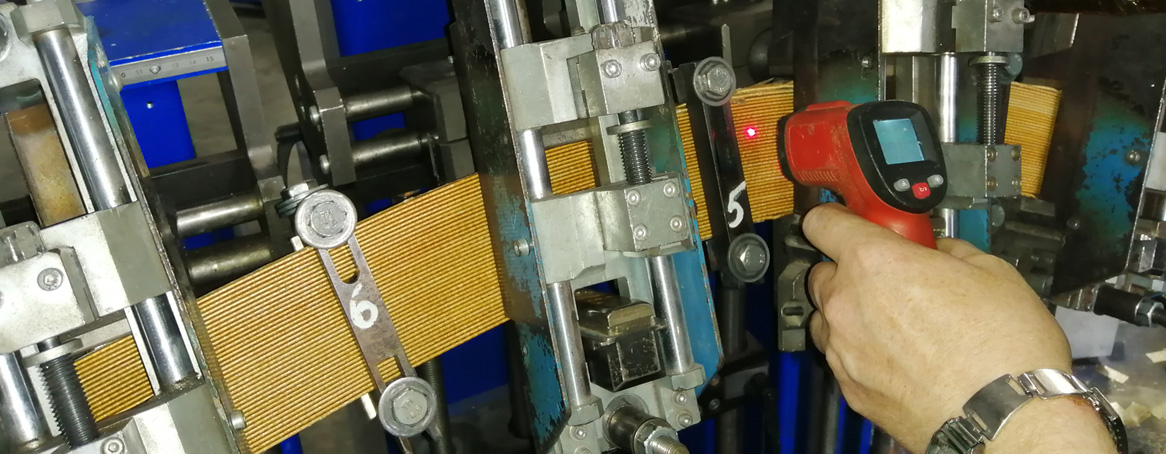

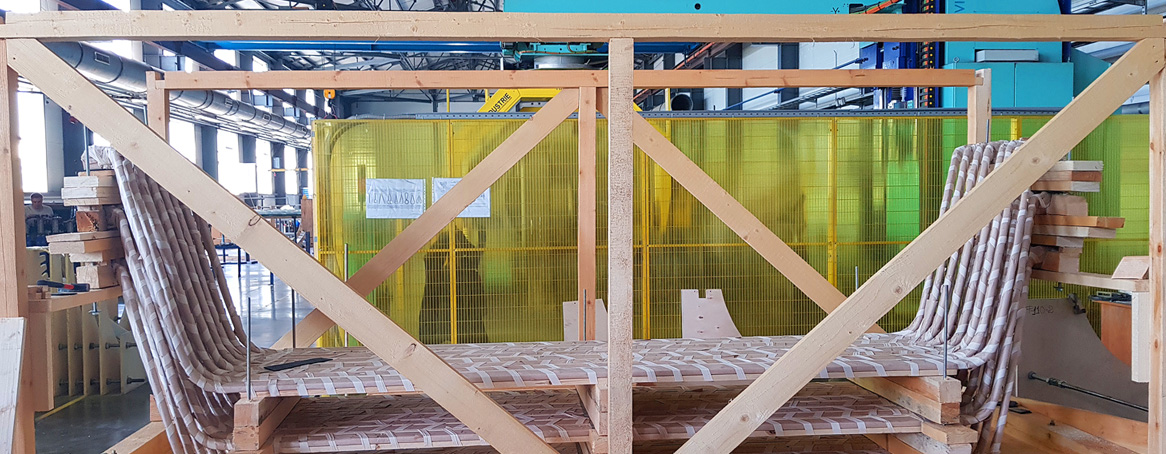

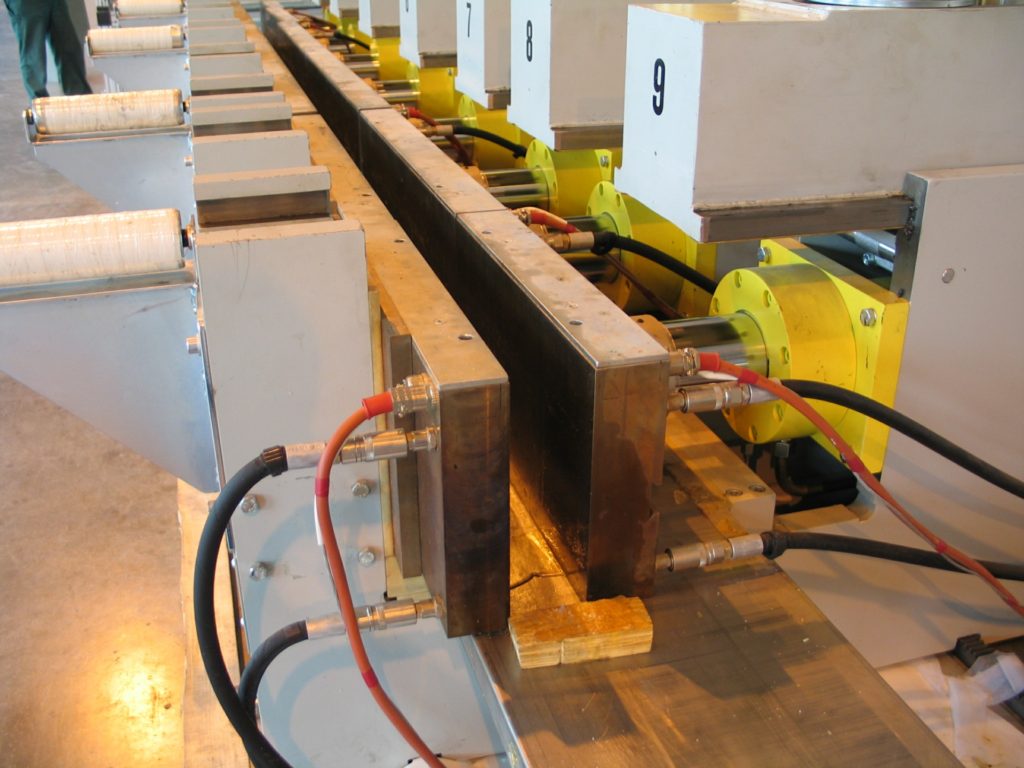

Пример качественно и некачественно выполненных стержней для статора турбогенератора

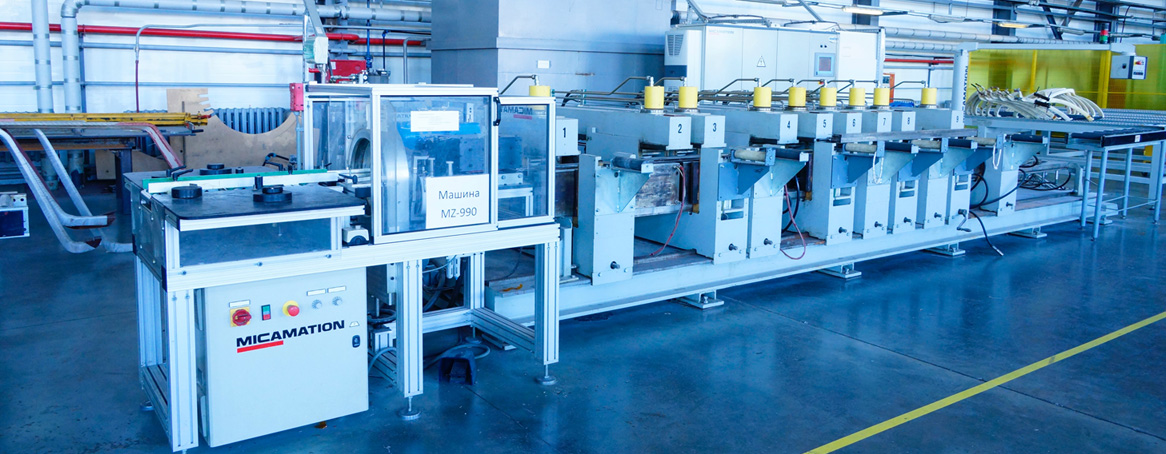

Спецпроект по импортозамещению – стержни генераторов завода «Электротяжмаш», г. Харьков

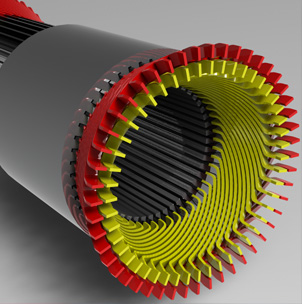

Генератор ТГВ-200

Стержень верхний к генератору ТГВ-200

Стержень верхний выводной к генератору ТГВ-200

Стержень нижний к генератору ТГВ-200

Стержень нижний выводной к генератору ТГВ-200

Генератор ТГВ-200М

Стержень верхний к генератору ТГВ-200М

Стержень верхний выводной к генератору ТГВ-200М

Стержень нижний к генератору ТГВ-200М

Стержень нижний выводной к генератору ТГВ-200М

Генератор ТГВ-235М

Стержень верхний к генератору ТГВ-235М

Стержень верхний выводной к генератору ТГВ-235М

Стержень нижний к генератору ТГВ-235М

Стержень нижний выводной к генератору ТГВ-235М

Генератор ТГВ-300

Стержень верхний к генератору ТГВ-300

Стержень верхний выводной к генератору ТГВ-300

Стержень нижний к генератору ТГВ-300

Стержень нижний выводной к генератору ТГВ-300

Генератор ТГВ-325:

Стержень верхний к генератору ТГВ-325

Стержень верхний выводной к генератору ТГВ-325

Стержень нижний к генератору ТГВ-325

Стержень нижний выводной к генератору ТГВ-325